Food Traceability Software

Food Traceability Software

- Contact Now for Immediate Pricing

- 1(800)-268-3269

- inquiry@interweigh.ca

Food Traceability Software

Looking for food traceability software that could save you millions in costly recalls? Our Interweigh Systems HACCP Link Software Item # ISISHIP was developed specifically with the random weight meat industry in mind. As an inventory control software, ISISHIP gives you the kind of control you'll need to avoid costly recalls of your meat and food products. Since meat and food processing often involves a variety of different food suppliers, being able to trace the source of the contamination to a single supplier, can significantly reduce the cost of a recall. Because of new food safety regulations and recent retailer mandates, traceability has become a hot topic in the meat processing industry. Meat processors have to demonstrate their ability to trace sources of food contamination from the point of origin to point of sale or lose business.

For more information download the iShip brochure.

Notable Features

- Use iShip software with the MC9200G Mobile Terminal.

- Provides the flexibility required on the manufacturing floor, in the warehouse, on the loading dock, and out in the yard as well as in the back room or out on the sales floor of a retail operation.

- Integrated 802.11 a/b/gWLAN radios.

- Exceptionally rugged construction.

- Forward scanning, pistol grip ergonomics.

- Use in a Windows environment or robust application-specific environment.

- Windows Mobile 7.0.

- Ideal for randomly weighted boxed products.

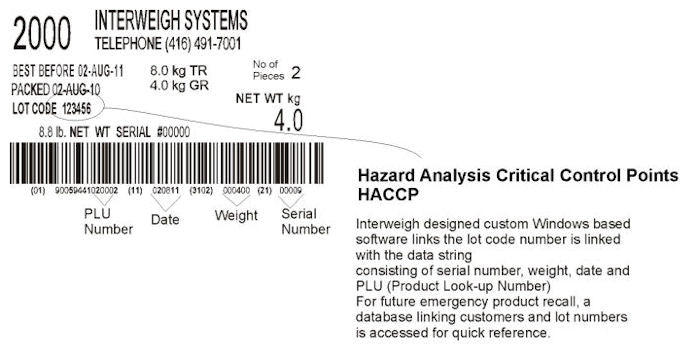

Not only is our ISISHIP software custom-designed for food processing companies that handle randomly weighted boxed products, but added data coordination can also provide them with an extremely tight HACCP (Hazard Analysis Critical Control Points) managed process. Instead of relying on paper forms, our software offers meat processing companies an automated way to comply with new food traceability requirements. With retail giants rolling out traceability mandates to all their suppliers, companies must be able to trace ingredients from source and products to the point of sale, allowing them to pinpoint problems when a food safety incident occurs, and to make recalls if necessary. Our food traceability software makes it easy to comply with traceability regulations and allows you to follow the path and quality of a food product through all the intermediate steps of its production process.

Below is a graphic outlining how Interweigh's HACCP Link Software works. Using a Zebra MC9200G (Portable Data Terminal) with the scanner, an operator scans the UCC standard bar codes on all the incoming or outgoing boxes of random weight products relating to particular customers or suppliers. A receiving or shipping manifest is then produced which either can be printed or downloaded to a PC.

The product that is originally packed in boxes crosses Interweigh's WL-7000 weigh labelling system and has a lot number assigned to it which relates to the point of origin. This lot number is printed on the label along with any other relative required information.

When the labelled box now enters the shipping area, an operator uses the scanner to the MC-9190-G terminal to prepare a picking slip for invoicing purposes and a packing slip for customer documentation.

Our food traceability software is also custom-designed to make it easier to integrate scale data with a customer's accounting and inventory software. This can be transmitted wirelessly to supply the quick and accurate information you need from your weighing devices. Our easy-to-use software programs offer several advanced features that are sure to help you streamline your operation. Our software packages allow you to easily connect any scale or balance with an RS-232, USB, 'Blue Tooth' or Ethernet output. It allows you to import the data from your weighing devices into your PC software.